Challenge

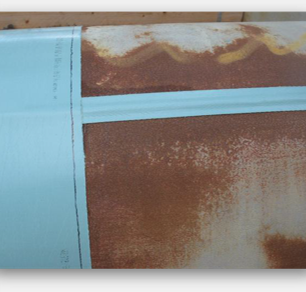

Rehab every 5 years on the coating was required due to;

- severe environmental conditions on site during application

- limited time for coating maintenance

- severe corrosion due to weathering and failure of existing coating system

- Severe exposure conditions (C5-I and C5-M)

- Stronghly reduced coating performance

Major Client Requirements

- Extending the service life of the asset

- Time and money saving solution

- Environmental, installation and worker safe approach

Solution

Effectively exceeded the client’s requirements while extending their maintenance cycles

- Eliminate blasting, tarping and conditioning

- No need for high power diesel generators, compressors, heaters (no emission and extensive logistics)

- Using a single component, non-aging coating system without any VOC

- Reducing the amount of PPE, breathing equipment, etc.

- Reducing the scafffolding strength, no abrasives weight to consider

- Increase productivity due to easy application in various climatcconditions

- Reducing waste and clean-up, no hazardous remains

- No effect on the refinery process